Inline PCB Cleaning

PCB Cleaning with rotating and oscillating ESD Brush

Efficient Cleaning of Printed Circuit Boards with ESD Brush

Inline PCB Cleaners with an rotating and oscillating ESD Brush. Very effectful cleaning process ideally right before the Screenprinter. The soft ESD brush cleans boards smoothly and removes particles efficiently from the board surface. Particles will be sucked away by the integrated powerful vacuum system and captured in a filter. We offer single side and double side Bruch Cleaners. Thanks to the very small inline length of only 350 mm, our Cleander Module requires minimal line space.

Inline Leiterplattenreinigungssystem

ESD Reinigungsbürsten in zwei Formaten: LP-Breiten bis 250 mm und bis 460 mm

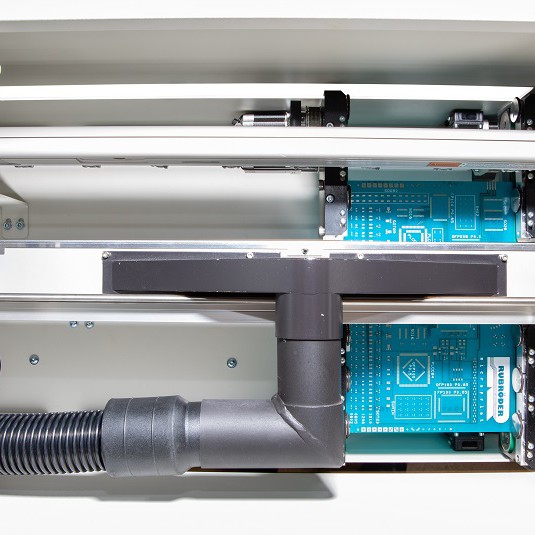

Buerstenmodul von oben

Inline PCB Cleaning System for ther cleaning of Boards before the Scrennprinting Process. Cleaning by Airknife and ionized Air. A Fan of ionized Air streams with high velocity on top of the PCB and takes away lose particles, which are contaminating the board surface and will be removed by the build in suction unit and transfered into the inbuild filter unit. Ionized Air prevents "gluing" of statically loaded particles.