Component Handling: for optimised production processes

Component Handling is a key process in modern electronics production, ensuring the smooth transport, precise positioning and safe handling of sensitive components. Whether during assembly, soldering or testing, precise and gentle handling is crucial for product quality. Automated Component Handling Systems play an indispensable role in order to increase efficiency in a mordern production environment.

Despite the initial investment, automated handling systems are more cost-effective in the long run because they enable higher production rates and minimise the error rate. They are essential for the reliable production of high quality products in large quantities.

At Rubröder, advice based on expertise, is the key. With decades of experience we supply tailor-made solutions for your component handling. From analysis to implementation, we support you in making your investment efficient and sustainable.

Perfect component placement - nozzles for every application

High quality nozzles and tips are critical to the smooth operation of your pick and place machines. Our solutions ensure accurate and reliable handling of all components, whether they are large, small, oddly shaped or made of different materials. With our products, you can ensure that your pick & place machines work efficiently and accurately, regardless of the manufacturer.

Pick & place machines are indispensable in electronics manufacturing, automatically placing components onto printed circuit boards. Whether for standard components or demanding special applications, our solutions are designed for maximum performance and durability. Rely on our expertise to increase the efficiency and reliability of your production.

Request detailed product overview

Feeder solutions for reliable component delivery

Feeders are a key component in SMT production to feed components reliably and efficiently. Rubröder offers three types of feeders for different requirements:

Feeders for blister tapes in widths of 8, 12, 16, 24, 32, 44, 56 and 72 mm.

Our electronic tape feeders for blister tapes enable precise feeding of SMT components in tape widths from 8 to 72 mm, regardless of the blister tape material. We offer standard and customised feeder benches for optimum feeder positioning.

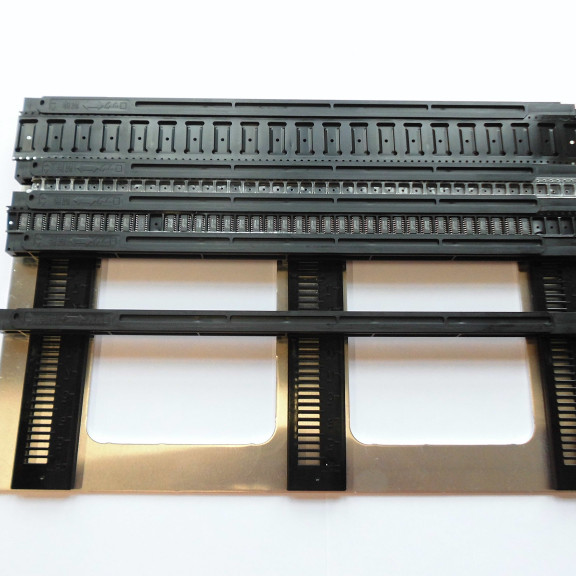

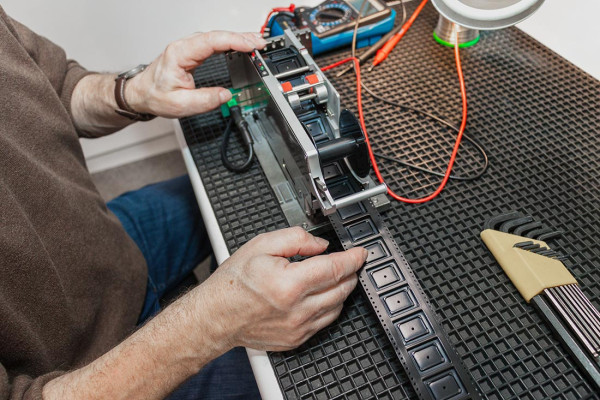

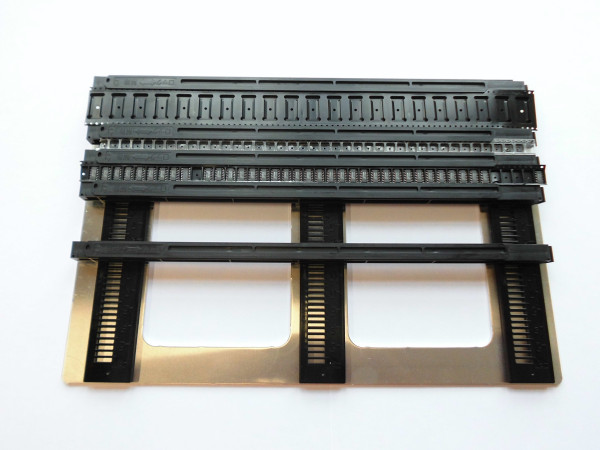

JEDEC Tray and Waffle Pack Handling Systems

The JEDEC Tray and Waffle Pack Feeder handles stacked trays or waffle packs with a separation mechanism and allows precise feeding into the assembly process. The modules are used to feed the components in the trays, to receive components from other production steps and to hold the components for storage.

Maximum efficiency: TapeTray for short pieces of tape

The TapeTray model NCSJ-S allows short pieces of blister tape to be processed quickly and easily in pick & place machines. It is ideal for reusing SMT components, for SMD evaluation processes or for feeding individual components. It is particularly useful for the efficient processing of remnants from component tapes. Handling is comparable to other trays, making integration easier.

Tape & Reel Systems for reliable component taping

Component taping plays a central role in electronics production to efficiently prepare components for the assembly process. Rubröder offers fully and semi-automatic Tape & Reel Systems that enable precise and fast taping. Fully automatic systems guarantee maximum efficiency for large quantities, while semi-automatic solutions offer flexible options for smaller series. Both systems optimise the taping process and ensure the quality of your production.

Your personal Contact Person

Wolfgang Riedel

Phone: +49 (0) 2622-943733

Fax: +49 (0) 2622-943750

E-Mail: w.riedel@rubroeder.de

Irene Veit

Phone: +49 (0) 2622-943735

Fax: +49 (0) 2622-943750

E-Mail: i.veit@rubroeder.de