Laser Marking: traceability without compromise

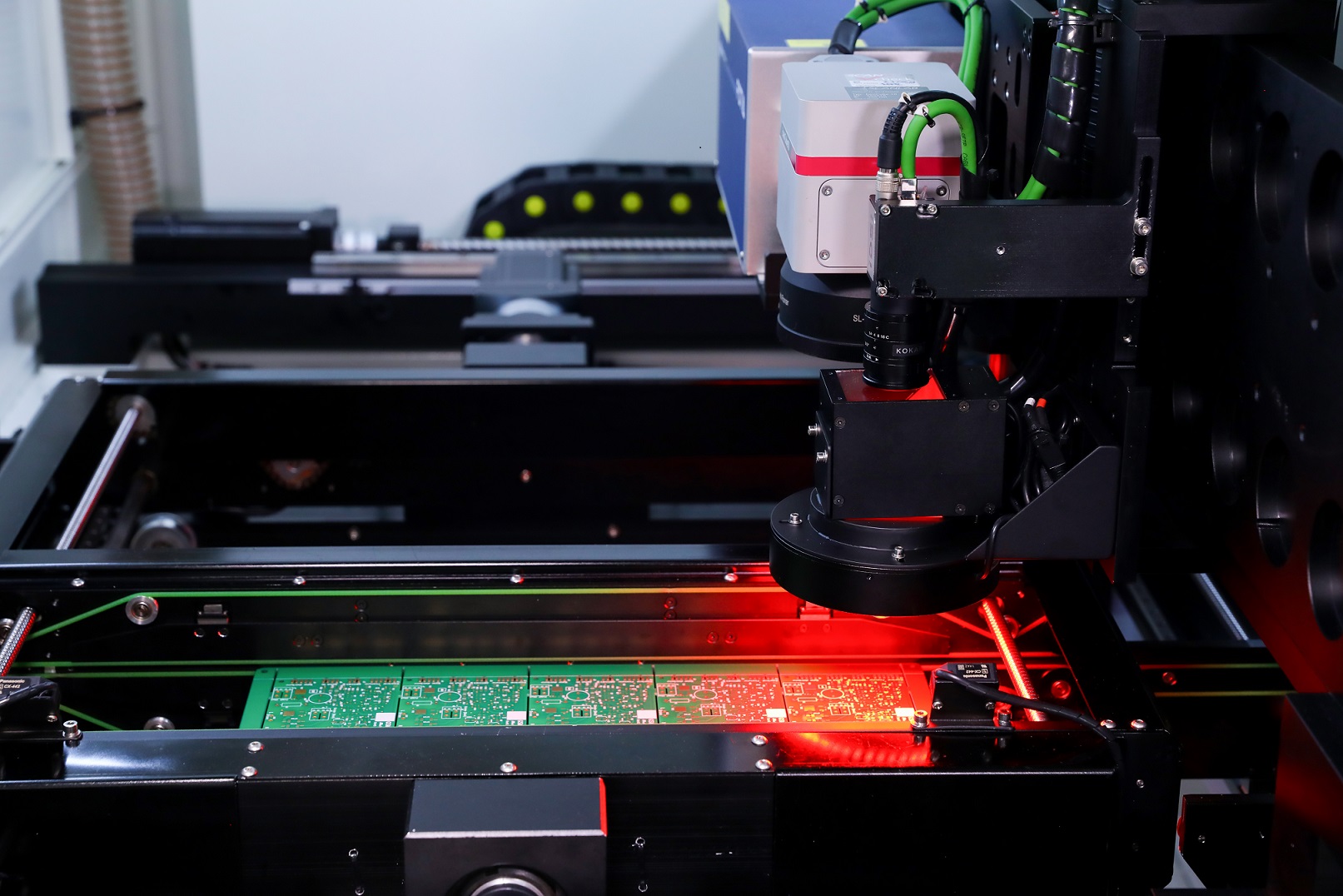

Laser Marking of printed circuit boards and ceramic substrates is the key to end-to-end traceability and significantly improved manufacturing quality in electronics production - while at the same time reducing costs. Precise marking of each product at the beginning of the process chain ensures complete documentation of all production steps. This gives you full control and transparency over your entire production process.

Our highly flexible Laser Marking systems enable you to individually and permanently mark assemblies before the first solder paste is printed. This cost-effective method ensures that all relevant information is reliably marked on each PCB. This not only makes your production more efficient, but also meets the highest quality standards.

With Laser Marking you invest in a technology that optimises your processes. You can rely on our systems to support your production with full traceability and reduced costs.

Features of Inline Laser Marking

Inline Laser Marking technology offers a wide range of powerful features that make your production processes not only more precise, but also more efficient. These advanced features ensure seamless integration into your production line and guarantee the highest quality and traceability in marking.

The main features of Inline Laser Marking:

- Marking depth control

- Marking height control

- CCD online inspection

- Barcode quality inspection

- MES System Link- Concentric CCD & Laser

- Laser Auto Control

Request detailed product overview

Safety through precision

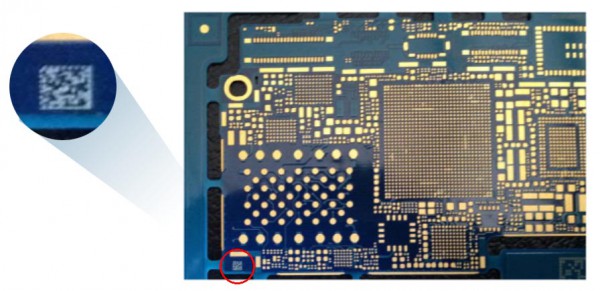

Quality and precision are crucial in Laser Marking. Our Mark Quality Check ensures that every marking meets these requirements. This system checks barcodes for greyscale, contrast ratio and the perfect shape of squares and circles by comparing them with a database. In this way, we ensure that every marking is precise and of optimum quality, guaranteeing error-free traceability and maximum reliability in your production.

Perfect legibility in the smallest space

When space on printed circuit boards is limited, precise, extremely small markings are essential. Our Laser Marking systems enable 2D codes on an area of only 1 x 1 mm, even under difficult conditions. This ensures maximum traceability and information density with minimum space requirements.

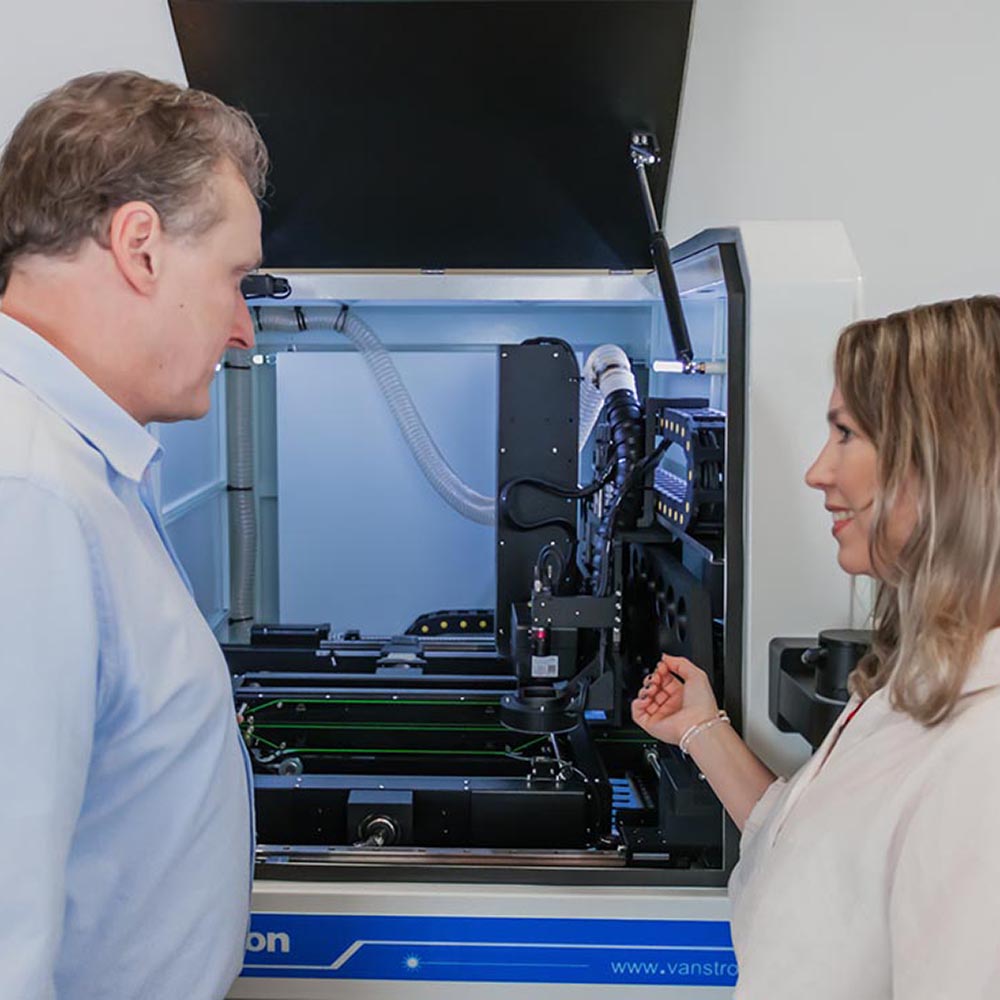

Rubröder - leading technology since 1980

Transform your production with Rubröder - your partner for advanced technology since 1980. Our solutions not only make your production more efficient and cost-effective, but also more environmentally friendly, giving you a decisive competitive advantage in today's market.

Highest quality: our precision technologies, such as Inline Laser Marking, ensure superior quality for each and every product.

Flexibility for the future: our adaptable systems adapt to your growing needs and secure your leading market position.

Low risk: From initial consultation to long-term support, we accompany you to ensure trouble-free operation.

Reliable supply: with our efficient warehouse management, we prevent production interruptions and secure your processes.

Technological leadership: by integrating the latest research findings, you are always one step ahead of the competition.

Your personal Contact Person

Wolfgang Riedel

Phone: +49 (0) 2622-943733

Fax: +49 (0) 2622-943750

E-Mail: w.riedel@rubroeder.de