Inline Cleaning PCBs: Precision begins with clean PCBs

In modern electronics production, even the smallest foreign particles such as dust, lint, abrasion, milling chips and laser particles can cause significant problems on printed circuit boards. As PCB structures become denser, these contaminants cause soldering and contact defects that affect product quality. Inadequate cleaning can even damage sensitive components and lead to complete failure.

Rubröder offers efficient cleaning systems that safely remove these particles at an early stage, even before stencil printing. This allows you to increase your first pass yield, reduce waste and minimise associated costs, while ensuring the quality and reliability of your production.

Reliable cleaning at every stage of production

In electronics manufacturing, thorough cleaning is essential to ensure product quality and reliability. Different cleaning technologies are used at different stages of the manufacturing process to remove contaminants and achieve optimum results. Two proven methods are used prior to stencil printing: mechanical cleaning with the ESD Brush, which prevents static build-up, and/or Airknife Technology, which effectively removes particles with a fan-shaped stream of ionised air.

After stencil printing, stencil cleaning is equally important. Ultrasonic stencil cleaning provides a gentle and thorough solution to completely remove solder paste residues and prepare the stencil for the next application.

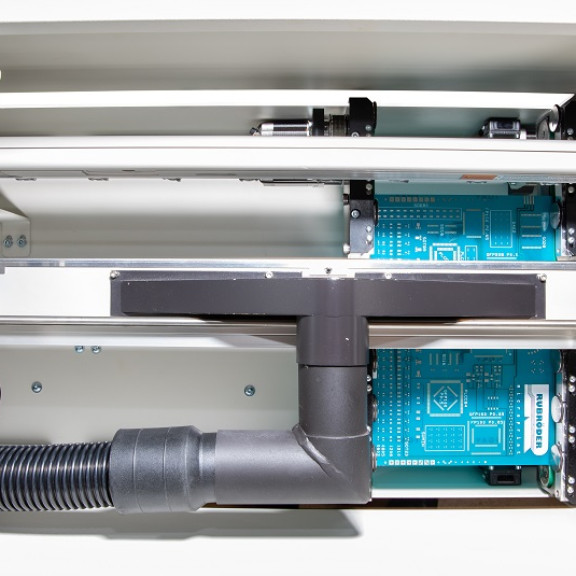

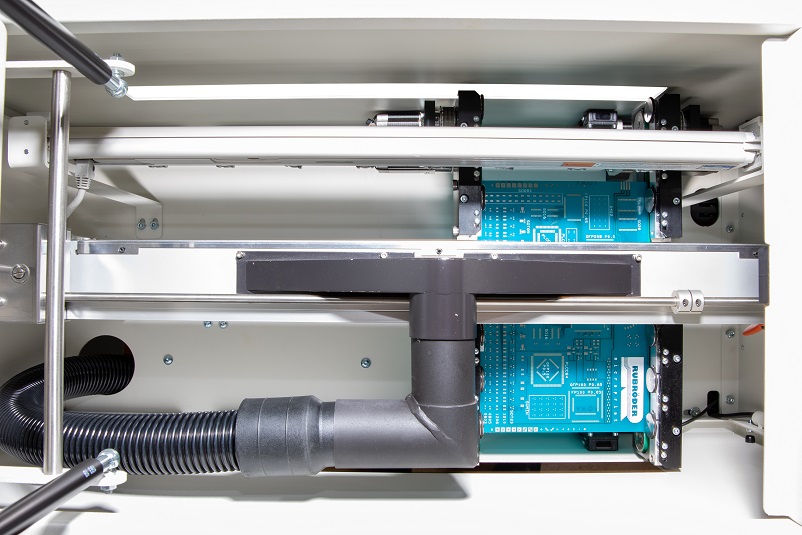

Cleaning with ESD Brush

Effective cleaning of PCBs prior to stencil printing is critical to remove contaminants such as dust, abrasion, or statically charged particles. The inline cleaning system and specially designed ESD Brush ensure thorough and gentle cleaning. The rotating and oscillating brush is made of ESD-compliant material that prevents static build-up. Loosened particles are reliably removed by an integrated suction system. We offer our systems for both single-sided and double-sided cleaning to ensure the optimum cleanliness of your PCBs

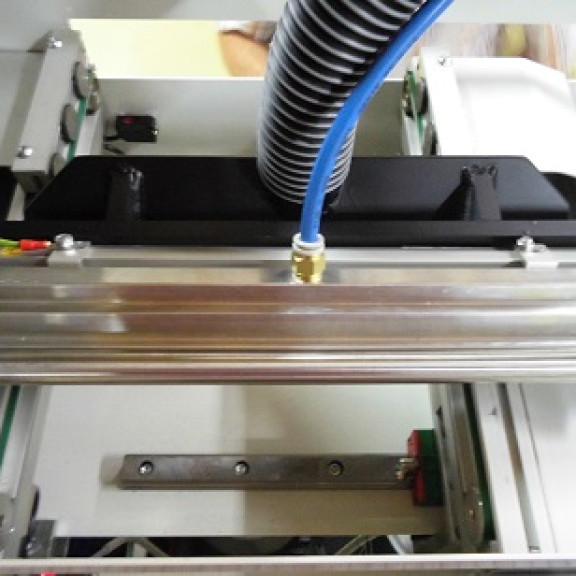

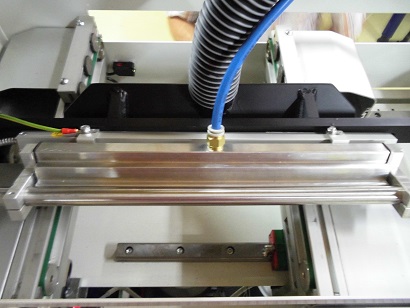

Cleaning with Airknife Technology

We rely on Airknife Technology for contactless cleaning of your PCBs. A fan-shaped airflow at high speed lifts loose particles from the PCB, which are then safely removed via an integrated extraction system. Thanks to ionised air, static charges are neutralised so that particles do not stick to the board. This process guarantees thorough and gentle cleaning of your PCBs and ensures an optimised production process.

Ultrasonic Stencil Cleaning

Our Ultrasonic Stencil Cleaning Systems offer safe and environmentally friendly cleaning without the use of solvent-based cleaning agents. With the water-based cleaning agent Detergent 440-R, which was specially developed for the ultrasonic cleaning process, your stencils are cleaned gently and thoroughly. This system ensures reliable and gentle cleaning that is perfectly tailored to the protection of your stencils and guarantees maximum cleanliness.

Your personal Contact Person

Wolfgang Riedel

Phone: +49 (0) 2622-943733

Fax: +49 (0) 2622-943750

E-Mail: w.riedel@rubroeder.de