Inline Selective Soldering Systems - maximum efficiency for your production

Our Inline Selective Soldering Systems are the perfect choice for companies looking to maximise production efficiency and throughput. These systems, including top-of-the-line models such as Fusion and Synchrodex, integrate perfectly into your production line to provide a fully automated solution that processes high volumes with impressive speed and precision.

With our inline systems, you can rely on technology that combines fluxing, preheating and soldering into one continuous, streamlined process. The result? Maximum reproducibility, top quality and a significant increase in your production output. Thanks to their modular design, the systems can be tailored to your specific requirements, allowing you to control and optimise the entire soldering process down to the last detail.

Request detailed product overview

Inline Selective Soldering Systems for all requirements

Our Inline Selective Soldering Systems are not only ideal for mass production, but also for the production of complex assemblies where maximum precision is required. The use of several soldering modules in line increases the throughput and flexibility of the soldering process and thus significantly increases your production output. In addition, reliable process control by monitoring all relevant parameters ensures maximum reliability and consistency in the soldering process. Our technology saves you time, reduces your costs and gives you an unbeatable competitive advantage.

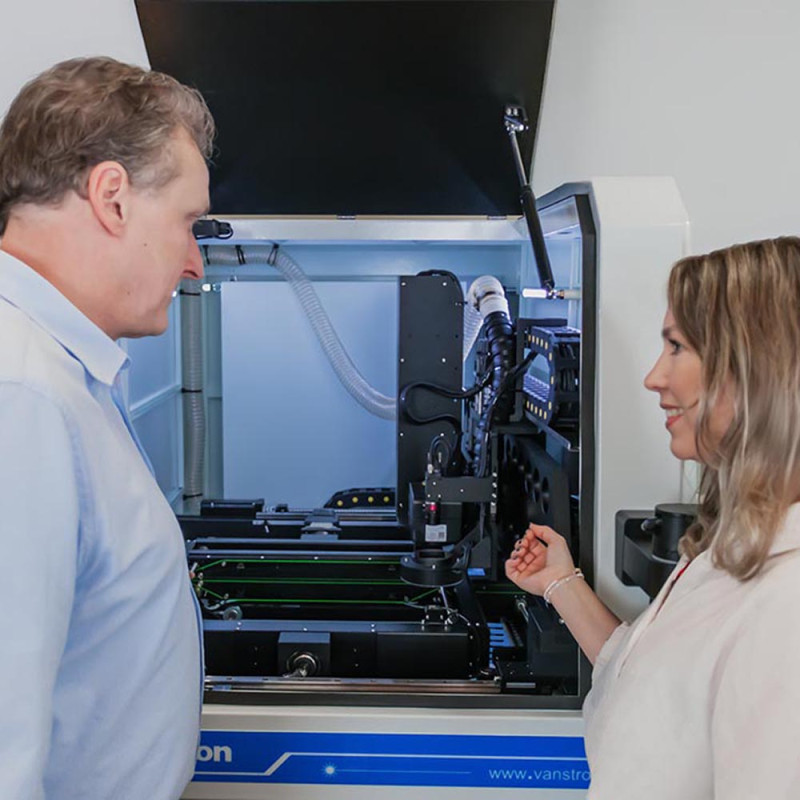

Fusion - Soldering system for fast cycle times and large batch sizes

The high speed selective soldering system Fusion is a highly flexible inline system for demanding production processes. With two (Fusion 2) to four (Fusion 4) process stations, it can be optimally adapted to your requirements and is ideal for fast cycle times and large batch sizes. Fusion supports board sizes up to 508 mm x 950 mm and offers flexible configurations with up to four solder pots. The integrated drop-jet fluxer ensures precise fluxing, while the inert soldering atmosphere with low nitrogen consumption and self-diagnostic control system guarantee maximum process safety and reliable production.

The right solution for every problem - Rubröder Factory Automation

Whether increasing efficiency, improving quality or implementing new technologies - our comprehensive portfolio offers the right solution. Our experts will advise you on the optimal combination for your needs. Discover the variety of our solutions and optimise your production. Contact us for a personal consultation to receive a concept tailored to your production.

- Cost efficiency: Tailor-made solutions reduce downtimes and lower your operating costs in the long term.

- Guaranteed precision: State-of-the-art technologies ensure consistently high quality.

- Future-proof: Our systems grow with your requirements and support your long-term planning.

- Operational continuity: Reliable service ensures smooth processes and minimises potential risks.

- Technological lead: The latest technology keeps you competitive.

Your personal Contact Person

Wolfgang Riedel

Phone: +49 (0) 2622-943733

Fax: +49 (0) 2622-943750

E-Mail: w.riedel@rubroeder.de