Synchrodex Pro

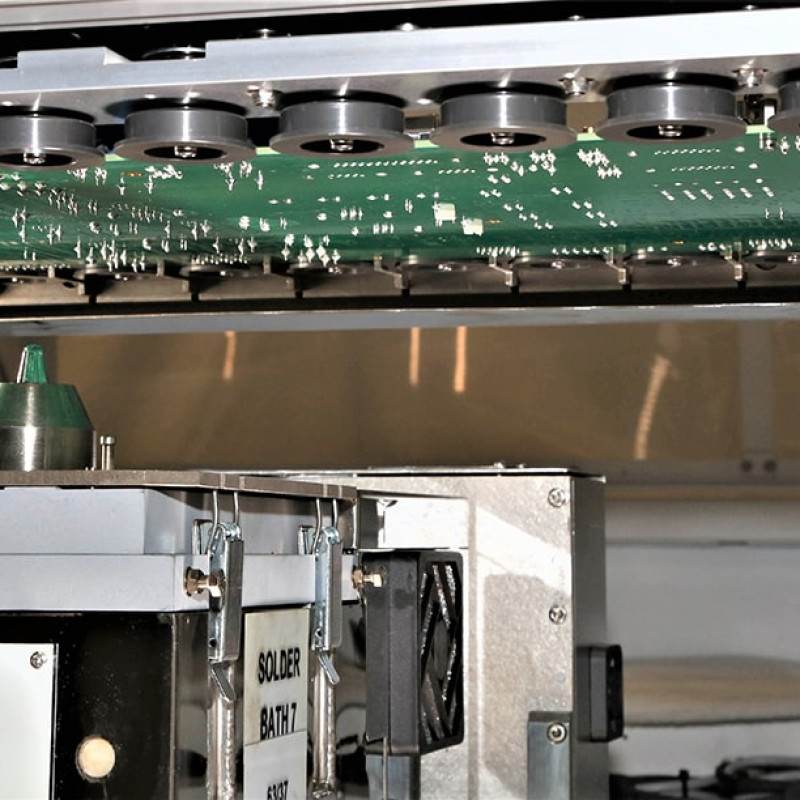

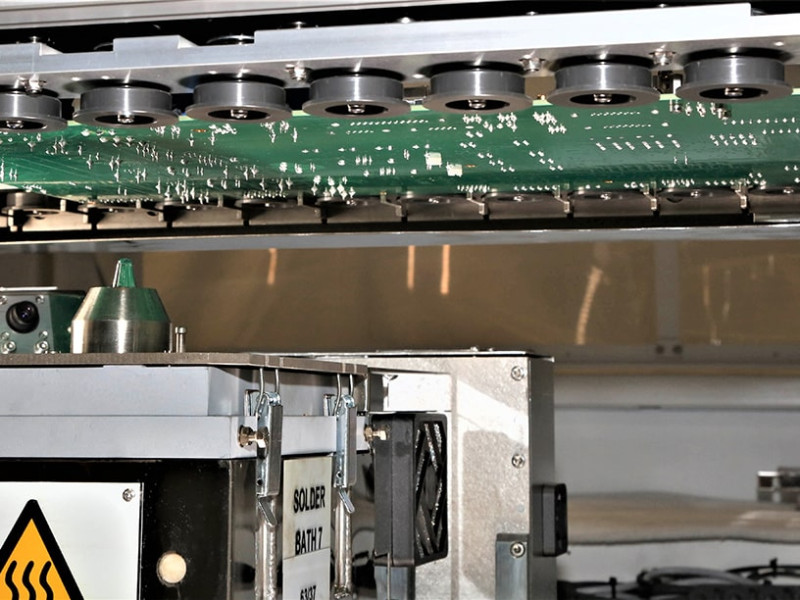

Our Synchrodex Pro is a modular system with a range of in-line equipment offering the ultimate in flexibility, with the ability to upgrade to high-speed throughput when multiple modules are placed together.

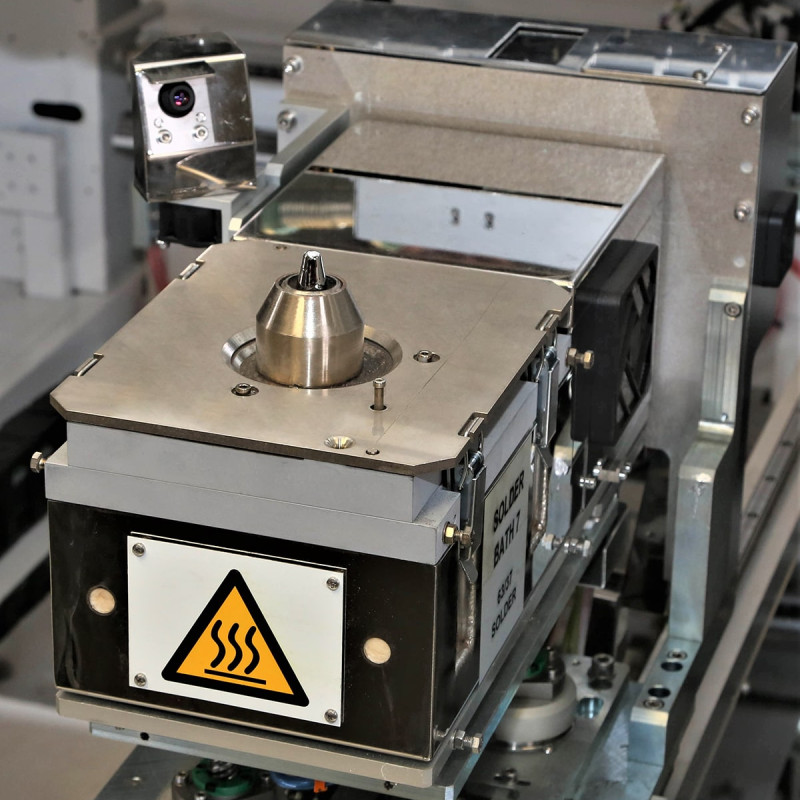

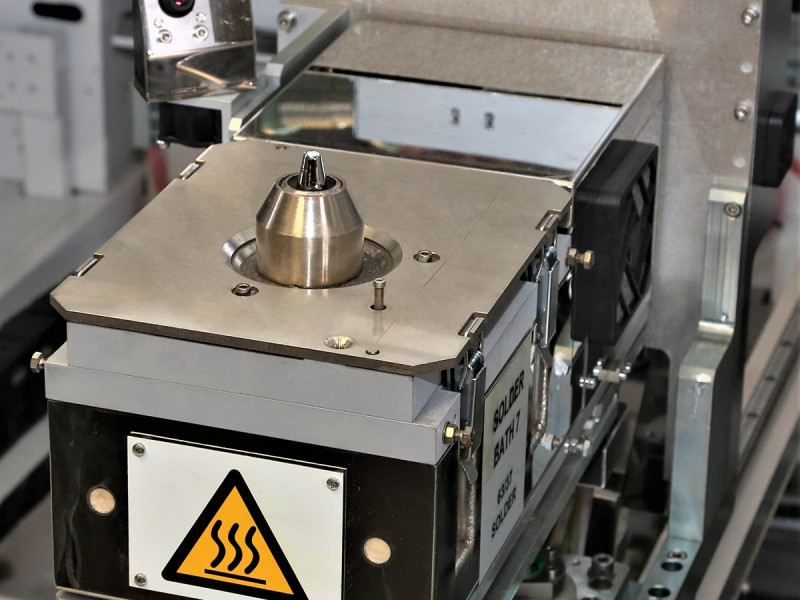

The standard Synchrodex Pro solder module is supplied with an on-board Drop-Jet flux head and offers optional top side and bottom side slide in/out infra-red pre-heat linked to closed-loop pyrometer control.

Our 1600mm solder module offers the ability to process PCBs using either a single or dual-bath operating format. Single bath operation allows for an alternate nozzle process on a single 610mm x 610mm PCB. Dual-bath operation allows for a dual-board, simultaneous, independent nozzle process for increased soldering flexibility on 420mm x 610mm PCBs. Pillarhouse’s uniquely flexible approach is facilitated via a software controlled, mechanical three pin stop arrangement on the conveyor section allowing for either single or dual PCB management. Our largest PCB handling capability of 1150mm x 610mm can be achieved when using the XL frame size.

Features

Features

- For PCB sizes up to 610 mm x 610 mm

- Easy adaptable for different Applications

- Useable for Inline and Stand Alone Prozesses

- Integrated Drop-Jet-Fluxer

- Ultrasonic Fluxhead for spezial Applications

- Automatic Solder Nozzle Conditioning

- Inert soldering atmosphere with low nitrogen consumption

- Control system with self-diagnostic

Options

- Micro Soldernozzles down to 1,2 mm

- IR PCB Topside Preaheat

- IR PCB Bottomside Preheat

- Pyrometer PCB Temperatur Measurement

- Measuring and Control of Solder Wave Height

- Laser based PCB Warp correction

- PillarPad Offline-Programing System

Request detailed product overview

Your personal Contact Person

Wolfgang Riedel

Phone: +49 (0) 2622-943733

Fax: +49 (0) 2622-943750

E-Mail: w.riedel@rubroeder.de